VDI 2770 - A prerequisite for the digital twin?

VDI, the Association of German Engineers and one of the main standardisation bodies in Germany, has published the VDI 2770 Part 1, a guideline which has come into effect on the 18th of October 2018. The aim of this guideline is to simplify the transfer of documents between manufacturers, retailers, operators and external service providers and to standardise the nature of manufacturer information (classification, structure, metadata and file format).

VDI, the Association of German Engineers and one of the main standardisation bodies in Germany, has published the VDI 2770 Part 1, a guideline which has come into effect on the 18th of October 2018. The aim of this guideline is to simplify the transfer of documents between manufacturers, retailers, operators and external service providers and to standardise the nature of manufacturer information (classification, structure, metadata and file format).

With this guideline, manufacturers of equipment and machinery, of content and document management systems, engineering companies and operators of process plants, authors and administrators of documentation as well as people involved in digital transformation projects have been given a new common task to master.

What exactly does the VDI 2770 Part 1 Guideline cover?

Companies must store and keep up-to-date a great variety of documents for each device. These documents contain information about the design, installation, commissioning, spare parts stocking, operation, inspection, maintenance, cleaning, repair, etc. of these devices. With more than five million technical goods which German companies acquire each year in order to build, expand or maintain production facilities, it was important to draw up a set of rules to manage all the necessary documents.

Furthermore, there are legal provisions which require manufacturers to provide specific documents, such as the CE Declaration of Conformity, ATEX certificates or material certificates. The new guideline streamlines the transfer of this information to the IT systems of plant operators and reduces the workload for manufacturers and operators. Standardisation facilitates, in this case, the fully automated transfer of a manufacturer's digital information as data objects from the manufacturer's IT systems to the users’ IT systems.

Through this standardisation, each individual piece of information will have a unique identifier in the future and thus it will be possible to locate it in all IT systems. As a result, the resource-intensive search in the manufacturers’ documentation will virtually be eliminated. This ensures that, while still using the same resources, technical information can be used more efficiently to improve process flows in production plants. Moreover, it saves time and reduces costs.

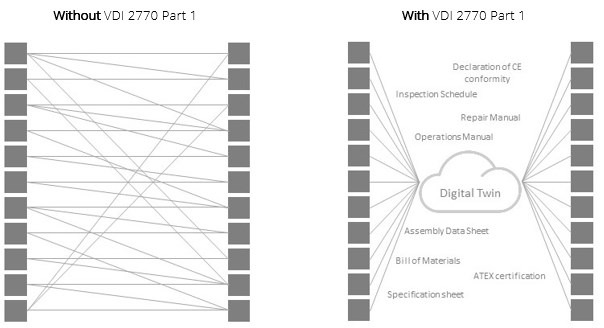

Quite often, the process of handing over documents between companies is used to maintain personal relationships as well as communication methods that have evolved over time. The data as well as the formats used for the transfer are very different. The fact that these data are handled in such different ways means that both parties have to invest a great deal of time and effort in preparing, processing and assuring the quality of the data.

What does the “digital twin” have to do with VDI Guideline 2770 Part 1?

If we take a closer look at the concept of the digital twin, we can see that it requires a consistent, standardised and above all error-free transfer of information between the systems.

To implement a digital twin you require three items:

- A physical object to be reproduced

- A virtual counterpart or agent associated with the physical object

- Information to map all components of the physical object to components in the digital world

A closer look at the graphic illustrating the way components communicate according to the VDI Guideline 2770 Part 1 and thus after the introduction of a digital twin (see above, right-hand side) reveals that binding rules for communication have been introduced with the new guideline. The guideline defines what kind of information documents should contain and at what stage of the process and in what form they should be available. It introduces a standard .

The goal of a digital twin is to maximise plant productivity, ensure safe operation and reduce costs in the medium to long term. These projects require high-quality, accurate data and information.

- Predictive maintenance and plant repair or maintenance using augmented reality require analyses based on reliable and relevant information, ideally supplemented by information provided by other users of the same systems. Also, manufacturers are required to provide step-by-step digital instructions. Thus, plants can be more productive, because failures can be predicted, and repair and downtime costs become more transparent and easier to plan.

- Downtime due to reportable incidents (OSHA incident rate) is reduced because safety-relevant documents and plant operating instructions are always available and up-to-date. It increases security and avoids the use of obsolete documents.

What are the next steps on the way to compliance with the VDI 2770 Part 1 Guideline?

Well-defined processes and consistent information are essential for the implementation of the guideline.

Is there an overview of all the systems that contain data needed to ensure that the necessary information on manufacturers can always be provided? How can you ensure that documents are always up to date? Do they contain all the necessary information?

Is there a defined procedure for processing data within a company and a description of the domains that customers and users of the facilities need?

Many questions need to be answered before implementing a guideline in a company. Organisations, processes and data need to be analysed and assessed. The guideline can only be implemented successfully once the basic principles have been established.

Read more about our strategic approach to data!

More about VDI guidline here (German): https://www.vdi.de/nc/richtlinie/entwurf_vdi_2770_blatt_1-betrieb_verfahrenstechnischer_anlagen_mindestanforderungen_an_digitale_herstelle/